SELECT AN ENCODER FOR THE APPLICATION – PART 1

Select an Encoder – Type

- Absolute encoder or Incremental Encoder: In normal is Incremental Encoder with lower price, easy to wiring, control.

- Rotary Encoder or Linear Encoder: We see rotary encode use for very many applications. You can easily make support, frame for that.

- Type of the shaft: Shaft encoder or Hollow shaft encoder, the diameter of the shaft, outside diameter of encoder… These values depending on your mechanics design.

- Simatic KTP700 Basic HMI and S7-200 PLC Communication Use RS485 Interface

- Download HMI Program Via USB Disk in TIA Portal Software

- S7-200 and WinCC Flexible. How to Make a Communication? Tutorial 1

Electrical Specification of The Encoder

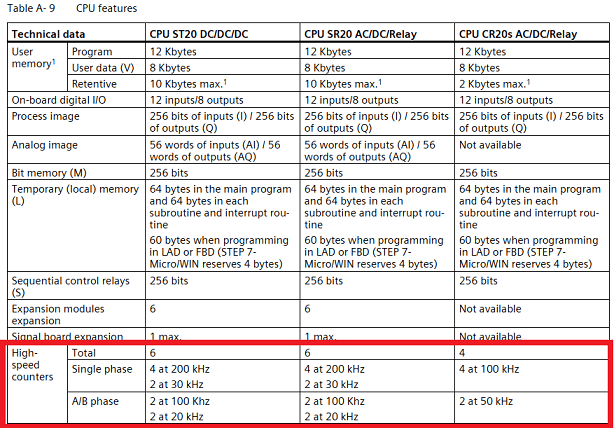

First to choose an encoder you need to note electrical specifications. It will affect your control panel design as power supply, Hight Speed Counter (HSC) equipment…Example About Select The Encoder

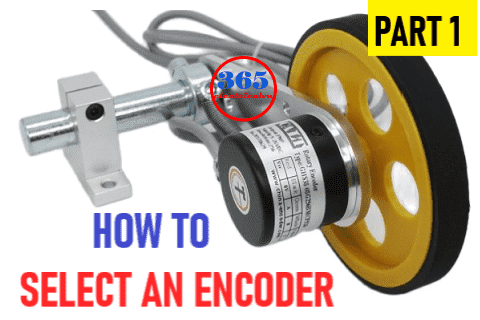

We SELECT AN ENCODER for a production machine as the right photo

We SELECT AN ENCODER for a production machine as the right photo- 1 – Coupling – support the encoder to mechanical part help you counter and calculate the length of the product, speed of motor …

- 2 – Mechanical support.

- 3 – Encoder

Update

Follow 365EVN on Facebook to get new information and more: 365EVN on Facebook.

-365evn-

If you find this content valuable, please rate it (click the button above), share it with your friends or invite me for a coffee by clicking the button below.