No products in the basket.

Basics of Servo Motor and Drive for Beginners in 5 Mins

The basics of servo motor and servo drive in 5 mins, for beginners before you start to use the servo motor and servo drive for your applications.

In this article, 365evn shows you the basics of servo motor and drive. An overview for beginners before you start to use the servo motor and servo drive for your applications. Presently and future the servo system using in very many applications from small to large, from production machines to the system industry. I will try to explain it in simple, easy-to-learn.

Contents

What’s Servo Motor and Servo Drive

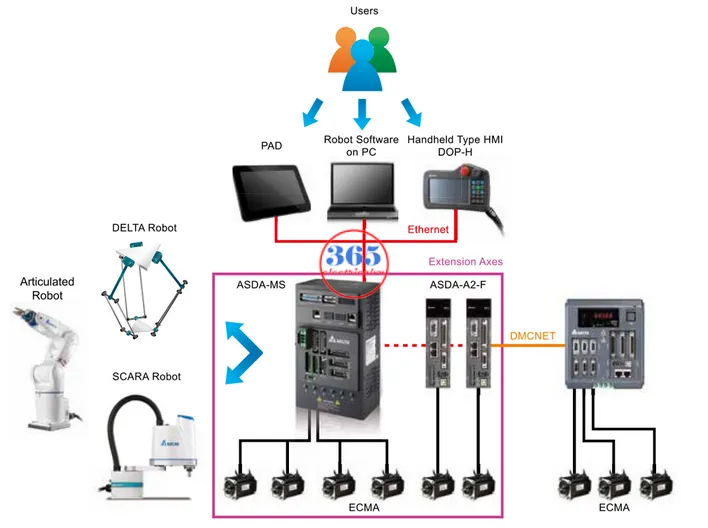

- The servo motor is a special motor that is used to control the movement of objects, a part of machines… It is a type of motor that is used in many different applications, such as in robots, and pharmacy … with high efficiency and with great precision.

- A servo motor includes a motor and an encoder with high resolution.

- The servo drive is an electronic amplifier to control the servo motor. Servo motor connect to drive by two cables: A cable to motor as normal motor you see and an encoder cable for feedback the signal position. In some motors, you can see more of a cable for the braking.

- A servo motor (motor + encoder) and a servo drive compose a closed-loop control system.

- You can read more about the basics of servo motor here.

- I do not explain in detail the components or working principles, with that you can refer more on the internet. In some cases, we can control it without knowing about that. You can start to learn about the basics of servo motor and servo drive by reading the manual (catalogue) from the manufacturer or here (I will update more documents frequently).

Basics of servo motor – How to control a servo motor?

- We can control the servo motor through an HMI, a Modbus connection, a PLC, an Arduino device…

- In this article and on the 365evn blog, I talk about the basics to control the servo motor through an HMI or a PLC

- In the most popular a servo motor is controlled by PLC. The PLC sends a series of pulses (High-speed output pulses) through the signal line to control the speed, the position and a signal to control the motor direction.

- We have three basics steps to control a servo motor:

- Servo drive installation: Connect the servo motor to the drive (it is easy – “plug and play”) and connect the drive to the controller (HMI, PLC…).

- Setting the parameters for servo drive: Depending on the control mode, we need to change some parameters to control it.

- PLC Programming (programming the controller) to control the servo motor: Each PLC brand supported a group instruction to control (called motion control). You can use it to control all servo.

- Do not worry, 365evn will guide you to learn about the basics of servo motor and servo drive step-by-step. Presently, I have a tutorial series about servo drive and motor on Youtube. You can refer here.

Servo motor vs Stepper motor

A typical question: What difference between a stepper motor and a servo motor? How I can select a servo or stepper motor? To my knowledge, selecting one depends on the application.

- Stepper motors are good for low price, low speed, low acceleration, and low accuracy (compared with servo motors). It is used for small and medium applications.

- Servo motors deliver higher efficiency and greater precision than stepper motors. However, the cost, size, and complexity are higher. It is used for all applications from small to large systems.

- If you working on the industry system with the PLC, HMI, SCADA… I recommend you learn more about servo motor and servo drive.

Basics of Servo motor and drive – Some questions?

- What is a hybrid servo motor?

A hybrid servo is a stepper motor and adds a feedback encoder signal. We can see the hybrid stepper servo was created to bridge the gap between the servo motor and the stepper motor. It brings to the system a quieter, smoother, precise position at a medium price. It is good for inertia loads and variable loads at low and mid-speed operation.

- Can I connect every PLC to the servo drive and control the servo motor?

No. To control the servo through a PLC, you need to check the type of output on the PLC. It must be transistor type. With that, read the PLC manual for more information.

- Can I connect a servo drive to another servo motor brand or vice versa?

No. Typically, each motor is designed to connect to a drive. You can not connect a servo drive to another servo motor brand or vice versa. Even, with a manufacturer, you can not connect them, if them is not in a series.

- Have a Servo simulator tool like PLC or HMI?

No. Until now, I have not seen any Servo simulator tool like PLC or HMI from the manufacturer. Have some servo simulator tools but it is only for Arduino devices. I recommend buying a servo (used device at a lower price) to learn and practice. You can refer some servo motor and drive on 365evn shop.

- I see, that the servo drive has very many parameters and terminals. Do we use it all?

No. From the basics level, we only use some parameters and terminals to control the servo motor. It is designed for a wide of applications. Depending on your application, some parameters and terminals might not be used.

Basics about servo motor – Servo motor control position on Delta ASDA-B2

- Refer to more videos about “Delta servo training” on 365evn: Link

Summary

Servo motor and drive systems are used in very many applications from small to large, from production machines to the system industry. Above, I showed the basics of servo motor and servo drive. Hope that it is helpful for you. Follow me on my website, Facebook, and YouTube… to get the newest content.

If you have any questions, comment below. Do not copy or re-up the content.

Next article: Servo Motor and Drive – Connection, Installation Basics In 3 Mins

–365EVN–

If you find this content valuable, please rate it (click the button above), share it with your friends or invite me for a coffee by clicking the button below.