How to Connect PLC and HMI. S7-200 & Delta DOP-B Communication

Hi, Everybody. To connect and control PLC by HMI, you need to make a connection (communication) between PLC and HMI (set by the software and linked by a cable). Today, I guide you step by step to do it. The example in this post: is connect PLC S7-200 and Delta HMI DOP-B (B07S411). For the other PLCs & HMIs, you can do it with the same method.

Select the method for connect PLC and HMI

By reading the catalogue and checking the support connection of PLC & HMI use in your project. If it not supported, you must change the PLC type (or HMI type) to connect the PLC and HMI

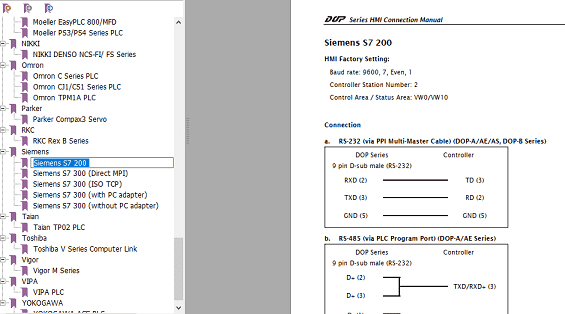

The example: I read the connection guide for Delta HMI DOP-B (“DOP Series HMI Connection Manual”). The document shows you, the methods that connect DOP HMIs & PLCs (RS232, RS485…). Some devices may support an Ethernet connection. Find your PLC type use (ex: S7-200).

-> I choose the RS485 method (via PLC Program Port) to connect S7-200 and HMI DOP-B.

Set the connection parameters on the software

The connection parameters for connecting PLC and HMI:

- Interface: RS485, RS232, Ethernet…

- COM port: COM1, COM2…

- Baud rate: 9.6 kbps, 19.2 kbps, 187.5 kbps…

- Data Bits: 7 bits, 8 bits

- Stop Bits: 1 bit, 2 bits

- Parity: Even, Odd…

- Station Controller Address

- Timeout, Retry Count, Delay time…

On Programmable Software of HMI

With the HMI Programs, the option name to set the connection parameters is different. Ex: With Delta, the DOPSoft program is a “Communication setting”. In normal, the default setting is ok (one HMI – one PLC).

On Programmable Software of PLC

With the PLC Programs, the option name to set the connection parameters is different too. Ex: With Siemens Step7 MicroWIN V4.0 program is a “Communication port” in System Block. With the PLC Program, you make the parameters the same as the HMI Program above for connecting PLC and HMI.

Note:

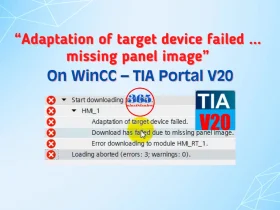

S7-200 processes a longer period of internal program scanning or inputs an interruption command, which may slow down the HMI response rate and cause a “Must Retry” or “No Such Resource” error message. The communication Delay function is suggested to avoid this problem. The parameter setting unit is ms and the suggested setting value is 10. The setting value should not be greater than 30 (By: “DOP Series HMI Connection Manual”).

The video guide connects PLC and HMI (S7-200 PLC and Delta HMI)

If you can not watch the video above, please check another link in my Video Area (V0084) or give feedback to me via WhatsApp, Email, or Message. Thank you!

Delta HMI Software Download

- Delta HMI Programming Software Download: Version 2.0 | Version 4.0

- All guide videos about PLC HMI, VFD and Servo programming by 365evn (Video area): Link

In the next post, I will show you: How to make the PLC & HMI connection cable.

-365EVN Automation-

If you find this content valuable, please rate it (click the button above), share it with your friends or invite me for a coffee by clicking the button below.